‘Water Battery’ poised to extinguish Lithium-Ion battery flaws

Recyclable “water batteries” that won’t catch fire or explode may sound like something from a fantasy novel, but a global team of researchers and industry collaborators led by Australia’s RMIT University has just developed them. Batteries of the future are here, now.

“What we design and manufacture are called aqueous metal-ion batteries – or we can call them water batteries,” said lead researcher Distinguished Professor Tianyi Ma, from the RMIT University School of Science.

The scarcity and high prices of the mineral lithium for lithium-ion batteries in electric vehicles is well known. The lightweight metal used for battery cathodes is mined in 10 countries, but the three largest lithium producers are Australia, Chile and China, which processes the majority of the world’s lithium.

Then there are the safety concerns left by the tragic history of battery fires in vehicles that run on lithium-ion batteries, and further worries about the suitability of lithium for large-scale grid energy storage in view of the propensity of lithium-ion batteries to catch fire.

The RMIT team uses water to replace organic electrolytes, which enable the flow of electric current between the positive and negative battery terminals. That means the water batteries can’t start a fire or blow up, unlike their lithium-ion counterparts.

The simplicity of manufacturing processes for the water batteries helped make mass production feasible, Ma said. “We use materials such as magnesium and zinc that are abundant in nature, inexpensive and less toxic than alternatives used in other kinds of batteries, which helps to lower manufacturing costs and reduces risks to human health and the environment.”

Ma said the team’s batteries were well suited for large-scale applications, making them ideal for grid storage and renewable energy integration – especially in terms of safety considerations.

“We recently made a magnesium-ion water battery that has an energy density of 75 watt-hours per kilogram – up to 30 percent that of the latest Tesla car batteries,” Ma said. This research is published in the journal “Small Structures.”

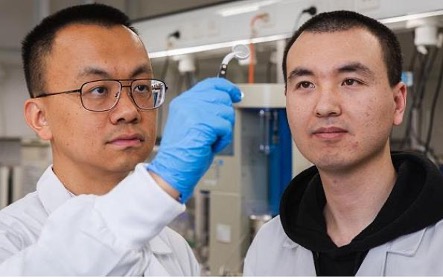

In the image below Distinguished Professor Tianyi Ma, left, and Dr. Lingfeng Zhu examine a water battery at RMIT University, Adelaide, Australia. (Photo by Carelle Mulawa-Richards, RMIT University)

“The next step is to increase the energy density of our water batteries by developing new nano materials such as the electrode materials,” he said.

Ma said magnesium is likely to be the material of choice for future water batteries. “Magnesium is lighter than the alternative metals, including zinc and nickel, has a greater potential energy density and will enable batteries with faster charging times and better capability to support power-hungry devices and applications.”

And at the end, magnesium-ion water batteries can easily become part of a circular economy. “Addressing end-of-life disposal challenges that consumers, industry and governments globally face with current energy storage technology,” Ma said, “our batteries can be safely disassembled, and the materials can be reused or recycled.”

The Lithium Race Could Be Left Behind

The world could face lithium shortages by 2025, the International Energy Agency (IEA) says, while Credit Suisse thinks demand could triple between 2020 and 2025, so the “supply would be stretched,” the World Economic Forum noted in July 2022.

About two billion electric vehicles need to be on the road by 2050 for the world to hit net zero greenhouse gas emissions, the IEA says, but sales of fully electric vehicles accounted for 9.5 million out of the 13.6 million EVs sold around the world in 2023, with plug-in hybrid EVs accounting for the rest.

The race to mine and process lithium to meet the global demand is on, but new technology often supplants the old, and the lithium race could be over as soon as it begins.

Australia alone produces 52 percent of the world’s lithium. Unlike Chile, where lithium is extracted from brines, Australian lithium comes from hard-rock mines for the mineral spodumene.

China, the third-largest producer, has a strong foothold in the lithium supply chain. Alongside developing domestic mines, Chinese companies have acquired around $5.6 billion worth of lithium assets in countries like Chile, Canada, and Australia over the last decade. It also hosts 60 percent of the world’s lithium refining capacity for batteries.

North America Now in the Race

In 2024, construction could begin or continue on lithium facilities in Arkansas, California, Nevada, South Carolina, Tennessee, and Texas in the United States, as well as Quebec, Canada. This follows the 2023 start of spodumene concentrate output, a raw material feed for lithium production, from North American Lithium in Quebec.

As the world produces more batteries and EVs, the demand for lithium is projected to reach 1.5 million tonnes of lithium carbonate equivalent (LCE) by 2025 and over three million tonnes by 2030, according to the Visual Capitalist, an online publisher on the global economy, markets, technology, and energy headquartered in Vancouver, British Columbia, Canada.

For context, the world produced 540,000 tonnes of LCE in 2021. Based on the Visual Capitalist’s demand projections, LCE production needs to triple by 2025 and increase nearly six-fold by 2030.

Although lithium supply has been on an upward growth trajectory, it can take from six to 16 years for new lithium projects to begin producing. As a result, the lithium market is projected to be in a deficit for the next few years, the Visual Capitalist predicts.

But the importance of lithium begins to diminish as other, less problematic technologies emerge.

”MAGNESIUM-ION WATER BATTERIES HAVE THE POTENTIAL TO REPLACE THE LEAD-ACID BATTERY IN THE SHORT-TERM, LIKE ONE TO THREE YEARS, AND TO REPLACE POTENTIALLY THE LITHIUM-ION BATTER IN THE LONG TERM, FIVE TO 10 YEARS FROM NOW.” – Distinguished Professor Tianyi Ma, RMIT University School of Science

Better Batteries With Water

A group of scientists from Hong Kong, China and the UK published their work on magnesium-ion batteries in the August 9, 2023 issue of the journal “Science Advances” in an article titled, “Next-generation magnesium-ion batteries: The quasi-solid-state approach to multivalent metal ion storage.”

They concluded that magnesium-ion water batteries appear to get around the problems caused by magnesium-ion batteries that use nonaqueous liquid electrolytes made up of complex salts and organic solvents.

These researchers explain that the poor conductivity of organic magnesium-ion electrolytes requires a high temperature to maintain battery performance. They also “need a moisture-free and oxygen-free environment and pose severe safety risks due to their toxicity and flammability, similar to conventional Li-ion electrolytes,” write the scientists, including co-author Kee Wah Leong in the Department of Mechanical Engineering, University of Hong Kong

“The battery serves as a proof-of-concept and demonstrates for the first time the long-term cyclability of an aqueous Mg metal battery,” Professor Leung said.

Magnesium-ion batteries offer a safe, low-cost, and high-energy density alternative to current lithium-ion batteries.

But, at this point, there are drawbacks to all technologies. While nonaqueous magnesium-ion batteries struggle with poor ionic conductivity, water batteries face a narrow electrochemical window, write Leong and his colleagues.

This group has designed a quasi-solid-state magnesium-ion battery (QSMB) for what they call “true multivalent metal ion storage.”

The QSMB demonstrates an energy density nearly five times higher than aqueous magnesium-ion batteries and a voltage plateau of 2.6 to 2.0 volts, outperforming other magnesium-ion batteries.

In addition, the quasi-solid-state magnesium-ion battery retains 90 percent of its capacity after 900 cycles at sub-zero temperatures down to −22°C.

”OUR QUASI-SOLID-STATE MAGNESIUM-ION BATTERY COMBINES THE BEST OF BOTH WORLDS, OFFERING THE HIGH VOLTAGE OF NON-AQUEOUS SYSTEMS AND THE SAFETY AND COST-EFFECTIVENESS OF AQUEOUS SYSTEMS. IT REPRESENTS A MAJOR STEP FORWARD IN DEVELOPING HIGH-PERFORMANCE MAGNESIUM-ION BATTERIES.” – Professor Kee Wah Leong, Department of Mechanical Engineering, University of Hong Kong

Batteries of the Future

“Considering the future of batteries, the electrolyte is probably the most important component. It’s not the most expensive, but it is the most important,” said Dr. Martin Winter, a professor of materials science, energy and electrochemistry at University of Münster, Germany as well as founder and scientific director of the Münster Electrochemical Energy Technology Battery Research Center.

“If the electrolyte is not compatible with all the cell components, the battery will never work. Lithium-ion batteries are very good already. Making them better step-by-step is tedious, and maybe not flashy to those talking about the ‘super battery of the future.’ And yet, it’s those step-by-step improvements that will get us to success,” Dr. Winter said.

For a quick run through of five of the most promising advanced battery technologies on the horizon, we turn to a Insider Monkey, a finance website that tracks hedge funds and corporate insiders. In a January 2024 article these five technologies were given the highest marks:

Silicon Anode Lithium-Ion Batteries

Graphite anodes for lithium-ion batteries reached their energy limit a long time ago. Instead, future anodes may be made of silicon. Silicon anodes enhance the energy density of lithium-ion batteries, and the performance of silicon is higher than graphite. It is cheaper than other materials, has fewer environmental impacts, and silicon anodes add a binder for better mechanical stability.

One drawback to a silicon anode is a short driving range; it also increases the mass of a vehicle, increasing its manufacturing cost.

Mercedes-Benz is the only automaker that has announced plans to use an advanced silicon carbon anode in a specific electric vehicle battery, the anode for the EQG G-Wagon. The anode’s manufacturer will be Sila, based in California.

NanoBolt Lithium Tungsten Batteries

Built mostly for electric vehicles and industrial uses, the NanoBolt lithium-tungsten battery is viewed as an improvement to lithium-ion batteries. These electrochemical cells have a layered structure that offers more surface area for ion transfer. The anode section of the battery is tungsten and carbon.

The NanoBolt allows the transfer of energy across the battery faster than the standard lithium-ion batteries, allowing a quicker, longer-lasting charge. Nanomaterials increase the available power from the battery, decreasing the time required to recharge.

LG Energy Solution, a South Korean battery company that produces the batteries for the Chevy Volt, Bolt EV, and Chrysler Pacifica is working on this battery technology.

Zinc-Manganese Oxide Batteries

Zinc-manganese oxide batteries use an alkaline electrolyte developed as a cost-effective electrochemical storage technology for grid applications. This battery is mainly targeted for grid-scale energy storage because of its high theoretical energy density rivaling lithium-ion systems, relatively safe aqueous electrolyte, established supply chain, and projected costs below $100/kWh at scale.

The use of water as an electrolyte in zinc-manganese batteries makes them safer than other forms of electrochemical cells. These batteries do not catch flames like lithium-ion batteries and offer better safety than lithium-ion batteries. Zinc is less costly than cobalt and lithium so manufacturing and using this battery can also reduce the cost of power storage.

The Japanese electronics company Sharp is developing a zinc-air flow rechargeable battery that uses zinc as a base metal, providing a large capacity and a high degree of safety, the company said in a statement.

Zinc-manganese dioxide batteries have dominated the primary battery market because of low cost, high safety, and easy manufacturing. It is “highly intriguing” to develop rechargeable zinc-manganese dioxide batteries say a group of Chinese chemists from the Ministry of Education and Nankai University. But, they observe, previous attempts were plagued by poor recycling performance.

Organosilicon Electrolyte Batteries

Organosilicon electrolyte is employed as a co-solvent in lithium-ion battery electrolyte to expand the temperature operability range in batteries, optimize cell life, and boost cell capacity.

Nontoxic and nonflammable with lower vapor pressure and a higher flash point than commercial alkyl carbonates, organosilicon works in liquid and solid electrolyte systems to improve lithium-ion battery performance. It offers higher energy density of lithium-ion and lithium-metal batteries with superior chemical and thermal stabilities.

The use of organosilicon is increasing, particularly in the EV industry and defense applications due to lower carbon emissions and reduced flammability as compared to lithium-ion batteries.

The market is estimated to rise with a compound annual growth rate of 64.8 percent from 2021 to 2031. Some of the key market players for this technology are Orbia and Silatronix.

Metal Hydrogen Battery

The metal hydrogen battery, also known as nickel-hydrogen battery, is a rechargeable electrochemical power source. It differs from a nickel-metal hydride battery by the use of hydrogen in gaseous form, stored in a pressurized cell.

By converting the chemical energy stored in gases into electrical energy, the battery can be used to power electric drive motors and temporary storage batteries. This battery has a charge efficiency of 85 percent and a cycle durability of more than 20,000 charge cycles.

Every first-generation hybrid vehicle has used nickel-hydrogen batteries, including the Toyota Prius and Honda Insight. Electric plug-in vehicles with these batteries included the General Motors EV1, first-generation Toyota RAV4 EV, Honda EV Plus, Ford Ranger EV and Vectrix scooter. Later models, including the Ford Escape Hybrid, Chevrolet Malibu Hybrid, and Honda Civic Hybrid, also use them.

But as of 2020 metal hydrogen batteries have been superseded by lithium-ion batteries in electric and plug-in hybrid vehicles. They remain in use in hybrid vehicles such as the 2020 Toyota Highlander.

The metal hydrogen batteries are attractive for electrical energy storage in satellites. For example, the International Space Station, Mercury Messenger, Mars Odyssey, and the Mars Global Surveyor are equipped with nickel-hydrogen batteries. They are also used in the Hubble Space Telescope, which is the first application of nickel-hydrogen batteries for a major Low Earth Orbit mission.

Toute l’actualité de Movin’On

dans votre boîte mail

Auteur

Partager

Tweets de @movinonconnect

Movin'On 2035 TODAY EP02 - Circular Economy & Competitivity

Movin’On 2035 TODAY EP01 – Fair Mobility for All https://x.com/i/broadcasts/1yNxagBrWZbGj

✨ THAT'S A WRAP!

Movin'On Summit 2024 has just concluded in Brussels!

More than 350 leaders and experts in sustainable mobility gathered to exchange ideas, collaborate, and share their vision for desirable and decarbonised mobility in Europe. Together, we explored ways to build…

🔴 Live from #MovinOnSummit2024

@AshaSumputh has just invited Denis Machuel, CEO at @AdeccoGroup and Florent Menegaux, President of the @Michelin Group & President of Movin'On

L’actualité de la mobilité durable

Découvrez les dernières tendances, des analyses thématiques et nos prochains rendez-vous